What's the Difference Between Hard Anodizing and Conventional Anodizing for Actuator Bodies?

1. Introduction

Anodizing is an electrochemical process that enhances aluminum's surface properties by creating a protective oxide layer. For actuator bodies—critical components in pneumatic and hydraulic systems—two primary methods are used: conventional (Type II) anodizing and hard (Type III) anodizing.

This article explores their key differences in thickness, durability, applications, and post-treatment, helping engineers and manufacturers choose the best process for actuator performance.

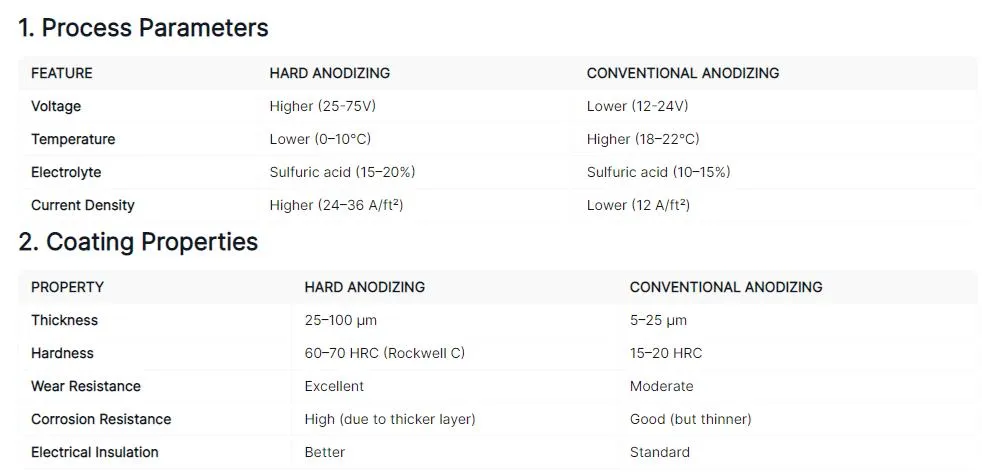

2. Key Differences in Process & Properties

3. Applications in Actuator Bodies

Hard Anodizing (Best for Demanding Environments)

High-performance pneumatic actuators – Resists wear in high-cycle operations

Industrial automation – Withstands abrasive particles and harsh chemicals

Aerospace & defense – Ensures reliability under extreme pressure/temperature

Oil & gas systems – Prevents corrosion in salty or humid conditions

Conventional Anodizing (Cost-Effective for Standard Use)

General-purpose actuators – Light-duty applications with minimal friction

Consumer-grade machinery – Decorative finishes with basic protection

Indoor equipment – Where extreme durability isn’t critical

4. Post-Treatment Differences

Hard Anodizing

Sealed with nickel acetate or Teflon for maximum abrasion resistance

Often dyed black for reduced glare and improved heat dissipation

Conventional Anodizing

Typically sealed with hot water or steam for basic corrosion protection

Available in multiple colors for aesthetic customization

5. Conclusion: Which Should You Choose?

While both processes improve actuator performance, hard anodizing is superior for heavy-duty applications due to its extreme wear resistance and thermal stability. Conventional anodizing remains a cost-effective choice for less demanding environments.

Why Jimai’s Actuators Stand Out

As a leading pneumatic actuator manufacturer, Jimai leverages hard anodizing to deliver:

Extended Lifespan – Hard-coated aluminum bodies resist wear in high-pressure systems

Corrosion-Proof Performance – Ideal for marine, chemical, and outdoor installations

Precision Engineering – Tight tolerances ensured by controlled anodizing thickness

Custom Solutions – Tailored surface treatments for specific operational needs

For actuators that demand reliability under stress, Jimai’s hard-anodized designs offer unmatched durability. Contact us to discuss your project’s requirements!