Powering Automation: Efficient Motion with

JIMAI Pneumatic Actuators

Pneumatic actuators are the workhorses of countless automation systems. Explore our extensive product line to find the best fit for your specific application.

Powering Automation: Efficient Motion with

JIMAI Pneumatic Actuators

Pneumatic actuators are the workhorses of countless automation systems. Explore our extensive product line to find the best fit for your specific application.

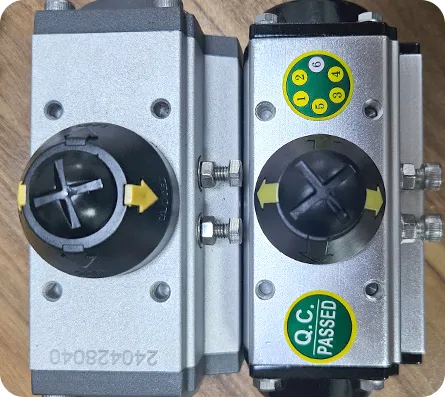

Comparing with others, JIMAI has below advantages:

1.Shaft material: JIMAI adopts ASTM5140 material, more durable and more resilient.

2.Shaft process: Every step of the process, from cutting the raw materials to the final product, is completed in-house by Jimai, and completed with the assistance of a robotic arm.

3.Star connection of shaft: JIMAI adopts hot punch process, which will increase the shaft hardness, while others use cold pressed .

4.Piston process: Processed by JIMAI own with the assistance of robotic arm.

5.End cover assemble: Assembly with actuator by automated screw machines, capable of installing eight screws simultaneously, to minimize deviations between the actuator body and end cover resulting from manual assembly.

Rotation degree: 0-45,45-90,0-90

Feature: Safe and explosion-proof

Application field: Oil refining, chemical industry

Operating Media: Air, Water,Gas, Oil, Steam

Rotating shaft: Nickel plated

Adopting Corrosion-resistant stainless steel screws.

Hard anodized cylinder, wear resistance

Highly responsive to the working instruction

Symmetrical rack and pinion structure to make it run smoothly and safely

Simple structure, exquisite appearance

Highly responsive to the working instruction

Hard anodized cylinder, wear resistance

Long service of life, can be used up to 1million times

X-RING configuration

Copper sliding mechanism

Enhance the composition of susceptible components

Front configuration of air connection and overhead arrangement of lifting lug

Every actuator undergoes 100% factory pressure testing to guarantee top-tier pneumatic performance.

Built for longevity with a lifespan of up to 1,000,000 operational cycles.

Meets international certifications including ISO5211, DIN3337, VDE3845, and NAMUR standards.

Manufactured with ASTM5140 high-grade steel for superior hardness, wear resistance, and operational stability.

Holds ISO 9001, 14001, CE, ATEX, SIL, and IP ratings for guaranteed quality and safety.

Backed by an industry-leading 18-month warranty for worry-free operation.

We understand that the heart of any reliable actuator lies in the quality of its materials. That's why we carefully select and process materials such as high-strength aluminum alloys, stainless steel, and high-grade polymers, and use even more sophisticated manufacturing processes.

ompared with our counterparts, our cylinder block has added hard oxidation process, which has a more durable service life.

In-house production of shafts, pistons, and cylinders.

One size doesn't always fit all. We understand that some applications require specific adaptations. That's why we offer a wide range of customization options to ensure our pneumatic actuators perfectly match your unique requirements.

Selection Basis: Choose based on torque requirements and application.

Common Types:

Rack and Pinion: Torque limited to approximately 6500 NM at 4 bar.

Scotch Yoke: Higher output torque, up to approximately 110,000 NM at 4 bar, suitable for larger valves.

Selection Basis: Choose based on required functionality (fail-safe operation, air consumption, etc.)

Common Types:

Double-Acting: Requires air to open and close. Typically A port opens, B port closes.

Single-Acting (Spring Return): Uses air to actuate in one direction and a spring to return. Can be normally open (air closes) or normally closed (air opens). Used in hazardous areas to prevent frequent air input if air supply is interrupted.

Customer Provides Torque: Easiest selection if customer provides valve torque with safety factor. Compare actuator torque (at specified air pressure) to valve torque + safety factor.

Customer Provides Information: If customer is unsure of torque, provide valve type, seal material, and size for model selection.

Emphasis: For spring return actuators, the spring torque is the critical factor to compare against the valve torque + safety factor. Double-acting actuators are typically verified under a pressure of 5 bar.

Customization Services: Offer various degree of rotation options beyond the standard 90 degrees.

Options:

0-180 degrees

0-120 degrees

0-135 degrees

Three-position: 0-45, 45-90, 0-90 degrees for precise flow control.

Customer Input: Customer specifies required degree of rotation.

Pneumatic actuators are essential for controlling chemical processes. They precisely regulate valve positions in pipelines carrying corrosive or hazardous materials, ensuring accurate mixing, batching, and flow control. They are also used to operate diverter valves directing flow to different reactors or holding tanks.

In construction, pneumatic actuators are used for precise positioning of equipment. They can control mixing operations in cement plants, adjust the tilt of solar panels, and operate louvers or dampers in large-scale ventilation systems within buildings.

Pneumatic actuators play a critical role in oil and gas extraction, refining, and transportation. They are used in valve control for pipelines, tanks, and processing equipment. They also control the position of nozzles during the filling of tankers, improving safety and efficiency.

These actuators are used to control material flow in processing equipment, such as regulating the flow of molten metal in casting processes. They can also be used for the precise positioning of tools in metalworking applications.

Pneumatic actuators are crucial in power generation and distribution. They are used to operate valves in power plants, control the position of solar reflectors in concentrated solar power (CSP) systems, and manage the operation of circuit breakers and switches in substations.

Pneumatic actuators are used in food and beverage processing for precise control over various operations, such as dispensing ingredients, opening and closing valves in filling machines, and adjusting the position of conveyor belts. They can be used in precise mixing applications and must comply with stringent hygiene standards.

Pneumatic Actuators

Frequently Asked Questions

We have compiled a list of frequently asked questions to help you better understand pneumatic actuators.

Find answers about sizing, maintenance, applications and more.

If you can't find the information you need, our team of experts is ready to help.

Talk to Our Expert

Quick Help: Contact one of our experts and we'll get back to you in 24 hours!