The Advantages of Carburizing Treatment for worm valve gearbox

The Advantages of Carburizing Treatment for worm valve gearboxOpening

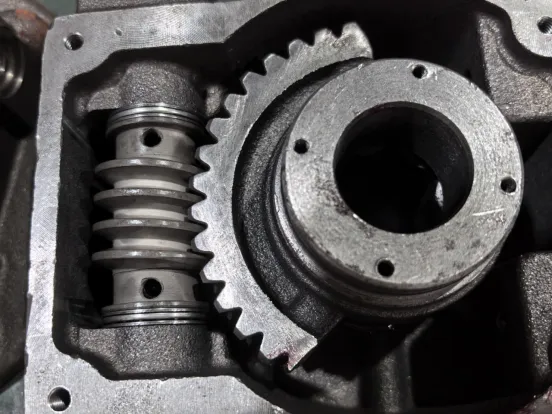

Carburising is a thermal treatment process that is frequently employed to improve the surface properties of low-carbon steels and low-alloy steels. Carburising enhances hardness, wear resistance, and fatigue strength while maintaining core toughness by disseminating carbon into the surface layer at high temperatures, followed by quenching and tempering. In this article, the primary benefits of carburising in industrial applications are examined.

1. Improved Surface Hardness and Wear Resistance

The primary advantage of carburising is the development of a high-carbon surface layer (typically 0.5–2.0 mm in depth) that undergoes quenching and attains an extremely hardness of HRC 58–64. This hardened layer offers exceptional resistance to abrasion, rendering carburised parts suitable for high-wear applications, including shafts, bearings, and gearboxes.

2. Strengthening of Fatigue

Carburising introduces compressive residual stresses on the surface, which significantly improves fatigue resistance. The service life of components that are subjected to cyclic compression, such as crankshafts and gearbox gears, is extended as a result of the reduced initiation and propagation of cracks.

3. Core Toughness That Was Maintained

The core's original low-carbon composition is preserved, assuring high ductility and impact resistance, as the surface hardens. This combination renders carburised parts appropriate for applications that necessitate both structural resilience and surface durability.

4. Consistent Treatment of Complex Geometries

Carburising uniformly processes intricate components, such as gears, cams, and irregularly shaped parts, in contrast to certain hardening methods that are restricted by the shape of the part. This is why it is an adaptable option for precision engineering applications.

5. Properties and Controlled Case Depth

Manufacturers can customise the treatment to meet specific operational requirements by adjusting carburising parameters (temperature, time, and carbon potential) to precisely control case depth and hardness distribution.

6. Compatibility with Secondary Processes

Post-carburizing treatments, such as quenching, tempering, and shot peening, can further improve mechanical properties, enabling optimisation for a variety of industrial needs.

Frequently Used Applications

Automotive: Camshafts, gears, and drive components

Cutting instruments, shafts, and bearings comprise machinery.

Gearbox components that are subject to high levels of tension in the aerospace industry

In conclusion

Carburising is a surface hardening technique that is extremely effective, providing superior core toughness, fatigue strength, and wear resistance. It is essential in industries that require high-performance metal components due to its adaptability to complex geometries and controllable case depth.

If you have any questions about carburizing technology or other heat treatment processes, or if you need customized solutions, please feel free to contact us.