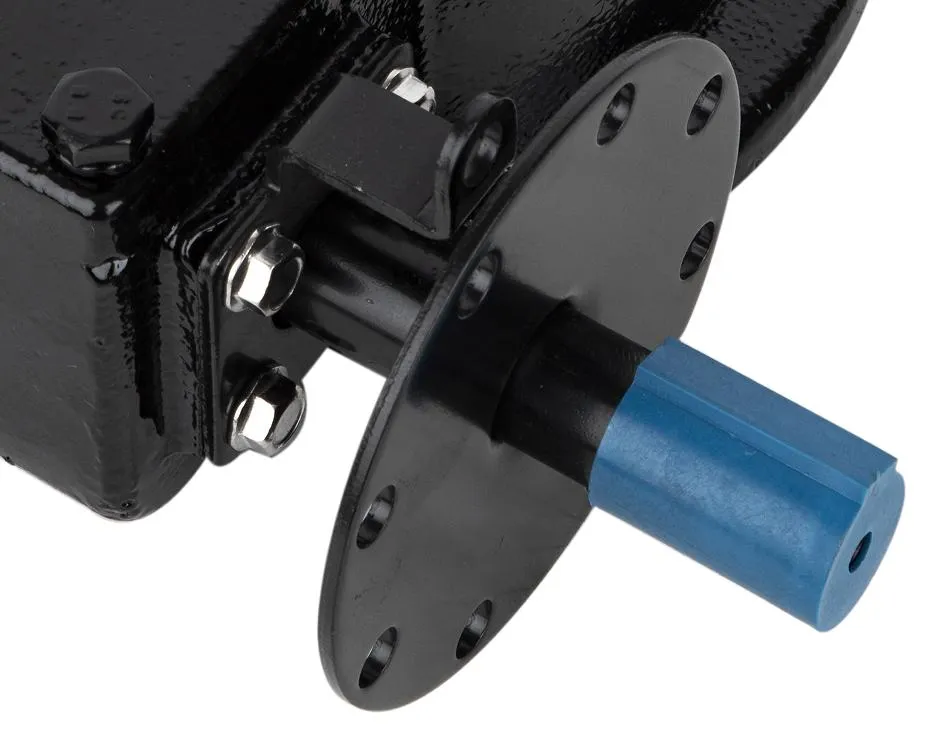

What Are the Benefits of Worm Gear Actuators (Valve Gearbox)?

Worm gear actuators, which are also referred to as worm gearboxes or worm-driven valve operators, are frequently employed in pipeline systems to regulate valves, including butterfly valves, ball valves, and gate valves. They are the preferred option in a variety of industrial applications due to the numerous key advantages they offer.

1. Torque Amplification and High Gear Reduction

Worm gear mechanisms are capable of a significant torque amplification from a modest input force, as they offer a high reduction ratio (typically 27:1 to 3655:1).

Suitable for the operation of valves with a large diameter that necessitate a high torque.

2. Self-Locking Capability

Reverse driving is challenging due to the friction angle between the worm and worm wheel, which prevents back-driving.

Reduces the likelihood of unintended movement by guaranteeing valve position stability, even in the presence of high fluid pressure.

3. Robust and Compact Design

Compared to other gear systems, they are space-saving, rendering them suitable for confined installations.

A long service life is guaranteed by the use of materials such as cast iron, stainless steel, or aluminum in the construction.

4. Quiet and Smooth Operation

Noise and vibration are diminished by the sliding contact between the worm and gear.

Suitable for applications necessitating subtle adjustments, this device offers precise control.

5. Low-Maintenance Needs

The necessity for frequent re-greasing is reduced by sealed lubrication systems.

Suitable for installations that are difficult to access or located in remote areas, where regular maintenance is a challenge.

6. Applications Versatility

Offering automation flexibility, this product is compatible with manual, electric, or pneumatic actuation.

Utilized in marine systems, HVAC, oil and gas facilities, water treatment, and chemical plants.

7. Cost-Effective

In comparison to other valve actuators (e.g., hydraulic or servo-driven systems), the initial cost is lower.

Minimal maintenance and a long longevity resulted in decreased operational costs.

In conclusion

Worm gear actuators are an exceptional choice for pipeline valve control due to their cost-effectiveness, durability, self-locking capability, and high torque capacity. Their versatility across industries makes them indispensable in fluid management systems.

As a leading manufacturer, Jimai further enhances these advantages by offering:

Superior Engineering & Precision – Jimai’s worm gear actuators are designed with high-precision machining and rigorous quality control, ensuring optimal performance and longevity.

Customized Solutions – Tailored designs to meet specific application needs, including extreme environments (high pressure, corrosive media, or extreme temperatures).

Advanced Materials & Coatings – Use of premium-grade alloys and anti-corrosion treatments to enhance durability in harsh industrial conditions.

Efficient Automation Integration – Compatibility with electric, pneumatic, and hydraulic systems, enabling seamless automation upgrades.

Global Reliability – Trusted by industries worldwide, Jimai delivers consistent quality, on-time support, and cost-competitive solutions.

By choosing Jimai, customers not only benefit from the inherent strengths of worm gear actuators but also gain a trusted partner committed to innovation and reliability in valve automation.