Advantages of Pneumatic Actuators Over Electric Actuators

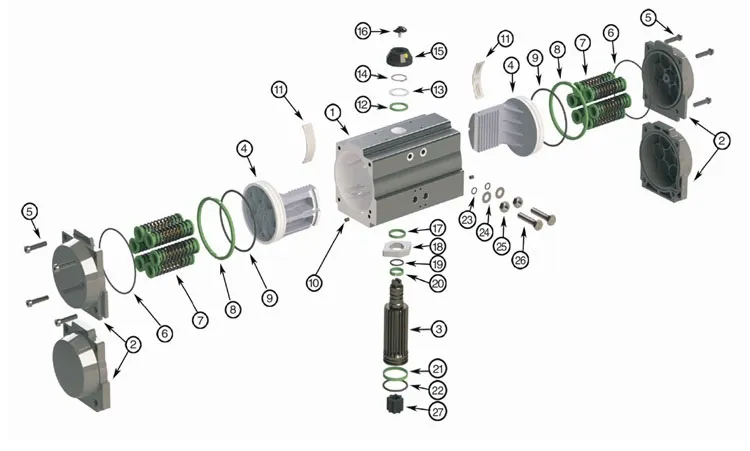

Both pneumatic and electric actuators are extensively employed in industrial automation, each offering unique advantages. Pneumatic actuators, such as those manufactured by Jimai, are distinguished by their cost-efficiency, durability, and high-speed operations, making them ideal for demanding industrial environments. In contrast, electric actuators provide precision and programmability but may fall short in heavy-duty applications. Below, we highlight the key benefits of Jimai pneumatic actuators compared to electric alternatives.

1. Cost-Effectiveness

Reduced Initial Cost: Jimai pneumatic actuators are typically more affordable than electric actuators, making them an optimal choice for budget-conscious applications.

Lower Maintenance Costs: With minimal electrical components and fewer moving parts, Jimai’s pneumatics require less upkeep, reducing long-term expenses.

Energy Efficiency: Compressed air systems can be more economical for repetitive, high-speed tasks compared to electric motor-driven solutions.

2. High Speed and Force

Faster Response Time: Jimai pneumatic actuators operate at high speeds due to the rapid expansion of compressed air.

Consistent Force Output: Unlike electric actuators, which may lose torque at high speeds, Jimai’s pneumatics maintain uniform force throughout their stroke.

Ideal for High-Cycle Applications: Perfect for tasks requiring frequent on/off cycles, such as sorting, clamping, and assembly lines.

3. Reliability and Durability

Robust Construction: Jimai pneumatic actuators are built to withstand harsh conditions, including extreme temperatures, moisture, and dust.

No Overheating Issues: Unlike electric actuators, Jimai’s pneumatics do not generate excess heat, making them suitable for continuous-duty operations.

Longer Service Life: With fewer electrical components, Jimai actuators excel in high-duty-cycle applications.

4. Safety and Compliance

Explosion-Proof Design: Jimai pneumatic actuators are inherently safe in flammable environments (e.g., oil & gas, chemical plants) since they don’t rely on electricity.

Industry Compliance: Preferred in pharmaceuticals, food processing, and cleanroom applications due to contamination-free operation.

5. Flexibility and Ease of Use

Simple Installation & Repair: Jimai’s pneumatic systems are easy to set up and troubleshoot, minimizing downtime.

Scalability: Expanding pneumatic systems is straightforward—additional actuators can be integrated without major electrical modifications.

Overload Protection: Jimai pneumatics can handle sudden shocks and overloads without damage, unlike sensitive electric actuators.

Conclusion

While electric actuators offer precision, Jimai pneumatic actuators are the superior choice for cost-sensitive, high-speed, and heavy-duty applications. Their simplicity, safety, and durability make them a preferred solution in industries like automotive, manufacturing, and food processing.

Choose Jimai for Reliable, High-Performance Pneumatic Actuators!