How Do You Install a Pneumatic Ball Valve Correctly?

Installation preparation prior to installation

It is imperative to verify the valves and accessories to ensure that the pneumatic ball valve's model and specifications satisfy the design specifications, including the pressure level, material, and connection method. It is imperative to verify that the valve is immaculate and free of rust or damage.

Subsequently, verify that the air source interface size and the pneumatic actuator model (such as single-acting/double-acting) are compatible. In order to prevent the valve from becoming obstructed or the sealing surface from being damaged, it is necessary to clean the pipeline of welding slag and impurities following the inspection.

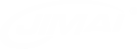

To guarantee that the flow direction is consistent with the arrow marked on the valve body, it is necessary to align the ball valve with the pipe prior to installation. When connecting the flange, it is necessary to align the gasket with the flange hole and evenly tighten the bolts (tighten in a diagonal pattern to prevent leakage). First, apply sealant or wrap the threaded connection with raw tape to prevent overtightening and the valve body from cracking. Tighten the connection manually and then use tools to reinforce it.

The actuator should be aligned with the valve stem and secured with matching bolts to ensure a secure connection.

Verify that the actuator's rotation direction corresponds with the valve's opening and closing directions. The actuator typically bears a "OPEN/CLOSE" designation.

Proceed to connect the gas source pipeline.

It is advisable to install a filter and a pressure reducing valve (adjusted to 0.4~0.6MPa). The solenoid valve should be manually operated or the gas line should be switched. The valve should be observed to ensure that it opens and closes smoothly and in the correct position. Connect the power supply (e.g., 24V DC/220V AC) and control signal line in accordance with the solenoid valve wiring diagram if it is controlled by a solenoid valve.

In the event that an air tightness test is necessary, input the design pressure and use soapy water to inspect the valve flange, threaded interface, and gas line connection for any leaks. Bubbles will emerge if there is a leak.

If a valve operation test is required, the solenoid valve can be triggered manually or through the control system to verify whether the valve switch action is sensitive and in place.

eg. Well assembled pneumatic ball valve with accessories