How Do You Control a Pneumatic Actuator?

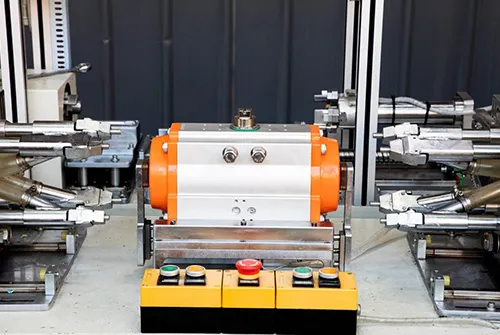

Pneumatic actuators are essential components in various industrial applications, offering reliable motion control through compressed air. Understanding how to effectively control these devices is crucial for optimizing performance and ensuring system longevity.

Methods of Controlling Pneumatic Actuators

Manual Control

Manual control is the simplest method, utilizing hand-operated valves such as levers, knobs, or push buttons. This approach is ideal for applications requiring direct, on-site adjustments.

Electrical Control

For automated systems, electrical control via solenoid valves and electrically-driven regulators is common. Solenoid valves enable on/off switching, while regulators fine-tune air pressure for smoother operation.

Proportional Control

Precision control is achieved using proportional solenoid valves and pressure regulators, which adjust airflow based on input signals. This method is perfect for applications requiring variable speed and positioning.

Key Considerations for Effective Control

System Design & Efficiency

Proper component selection and efficient piping layouts minimize pressure loss and ensure consistent airflow. High-quality valves, regulators, and tubing enhance performance.

Maintenance & Quality Components

Regular inspections prevent leaks and component wear. Using certified, high-quality parts—like those from JIMAI—extends actuator lifespan and reduces maintenance costs.

Safety Measures

Overpressure protection (e.g., relief valves) and emergency shutdown protocols safeguard personnel and equipment.

Advanced Control Techniques

- IoT & Smart Systems

Integrating pneumatic actuators with IoT-enabled systems allows real-time monitoring and remote adjustments, improving efficiency and predictive maintenance.

- Adaptive Control

Machine learning algorithms optimize actuator performance, reducing energy consumption and wear.

Why Choose JIMAI Pneumatic Actuators?

As a leading valve automation solutions provider, Zhejiang Jimai Auto-Tech Co., Ltd. combines innovation, precision, and reliability in manufacturing high-performance pneumatic actuators.

Key Advantages:

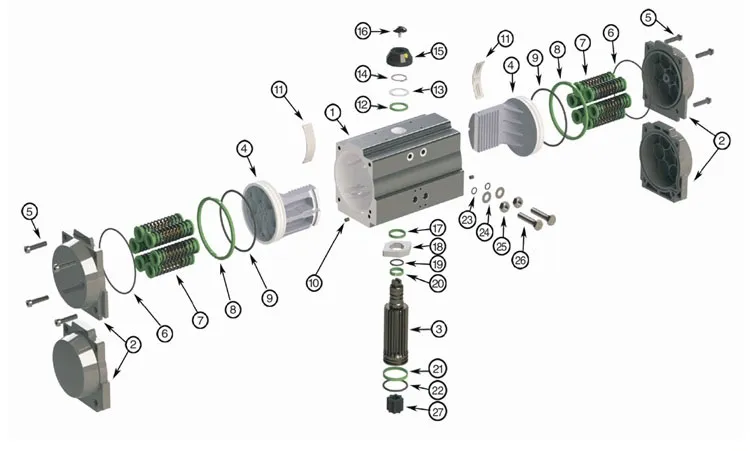

In-House Machining Expertise – With 140+ machines, JIMAI independently processes all components, ensuring superior quality from raw materials to finished products.

High-Precision Rotating Shaft – Our actuators feature a high-concentricity shaft, eliminating jamming and ensuring smooth, precise rotations.

Exceptional Durability – Designed for 500,000+ cycles, JIMAI actuators operate flawlessly with minimal maintenance.

Advanced Leak Testing – Our digital leakage detection systems provide precise diagnostics, ensuring airtight performance.

Industry-Leading Solutions:

With 20+ years of experience, JIMAI serves industries like power plants, petrochemicals, water treatment, and urban infrastructure, delivering customized, high-efficiency automation solutions.

Conclusion

Controlling pneumatic actuators effectively requires the right methods, system design, and quality components. By leveraging manual, electrical, and proportional control, along with smart technologies, industries can maximize efficiency and safety.

For reliable, high-performance pneumatic actuators, JIMAI stands out with precision engineering, durability, and cutting-edge testing. Explore our solutions to enhance your automation systems today!

Learn more at [JIMAI’s official website].