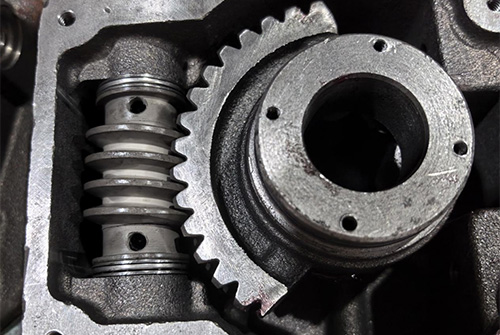

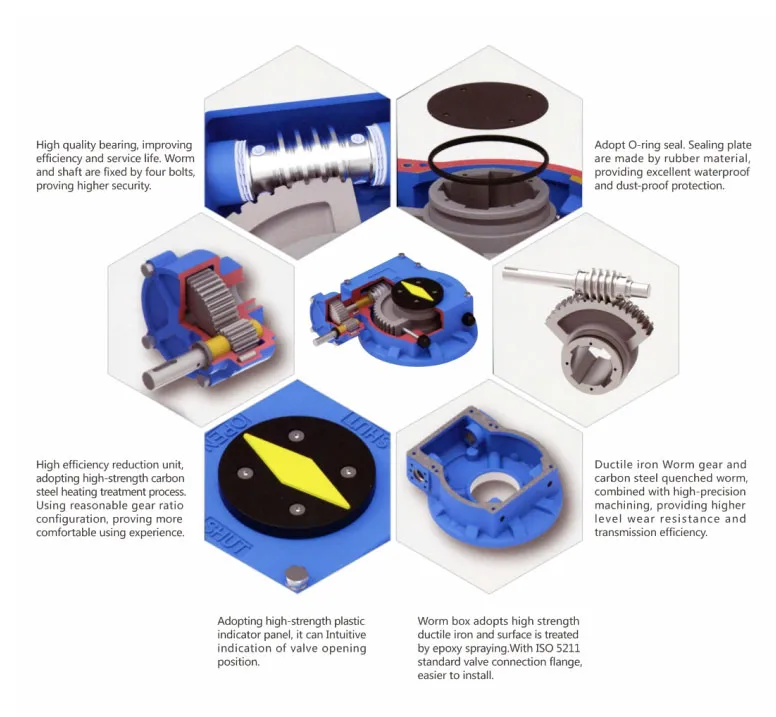

Own Process Body and Worm Gear

The valve gearbox body and worm gear are processed independently by JIMAI. The valve gearbox's overall quality is guaranteed by JIMAI's processing of all primary components. The tight connection guarantees a seamless rotation without any jamming. The maintenance cost will be significantly reduced by utilising JIMAI products.

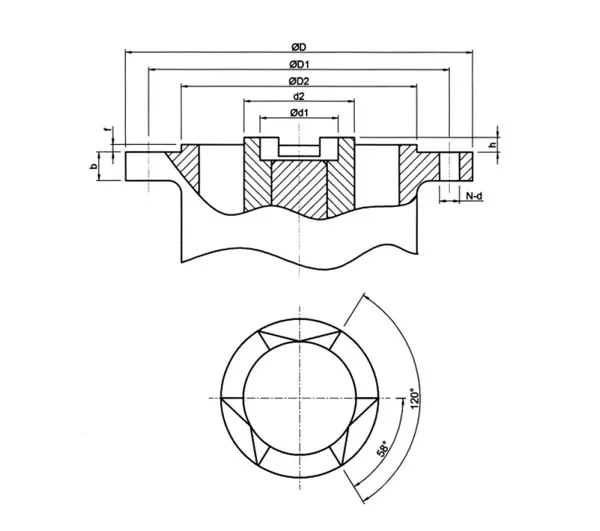

Carburization Treatment Worm

JIMAI offers high-strength worms that have been treated with carburisation. This process significantly enhances the worm's hardness, ensuring that it will not break during extended use. Consequently, the maintenance cost can be significantly reduced by utilising JIMAI products

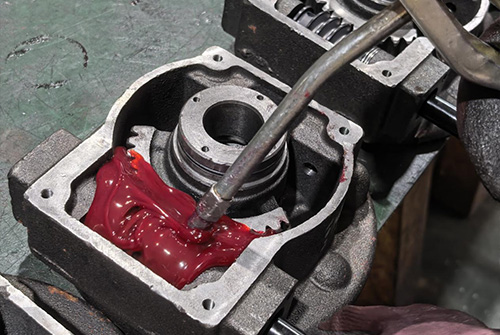

Low Temp lubricant

JIMAI employs a low-temperature lubricant that is suitable for use in temperatures ranging from -40°C to 120°C. Our lubricating oil is applied to the entire worm gear to guarantee a highly seamless operation.

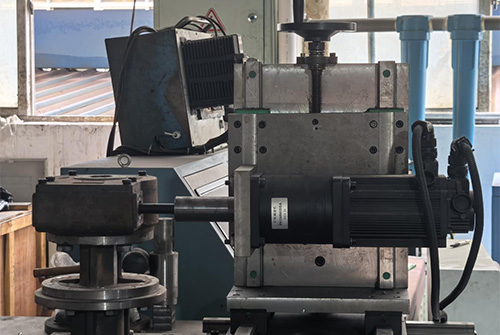

Torque Testing Machines

Professional torque testing devices are available from JIMAI for valve gearboxes of any size. JIMAI guarantees precise torque data for each valve gearbox variant. Before departing the factory, each input torque and output torque undergo rigorous testing.

CATALOGUE DOWNLOAD

CATALOGUE DOWNLOAD