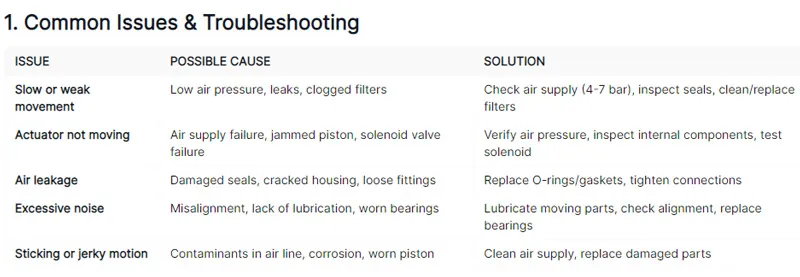

Maintenance and Repair Guide for Pneumatic Actuators

Introduction

Valve control and motion applications are among the most prevalent applications of pneumatic actuators in industrial automation. In order to guarantee reliability and endurance, it is imperative to conduct appropriate maintenance and repair. Key components of pneumatic actuator maintenance, troubleshooting, and repair procedures are addressed in this guide.

2. Repair Procedures in Detail

A. Inspection and Disassembly

Shut off and depressurize the actuator to isolate the air supply.

Detach the actuator from the valve/linkage by removing the mounting fasteners.

Carefully disassemble the actuator to inspect its internal components by opening the enclosure.

Inspect the seals, piston, springs, and bearings for wear and damage.

B. Replacement of O-rings and seals

Use a soft implement to remove the old seals, being careful not to scratch the surface. Before installing new seals, apply pneumatic lubricant.

Guarantee that the components are aligned correctly during the reassembly process.

C. Maintenance of Pistons and Cylinders

Use a lint-free cloth to clean the cylinder chamber.

Check for corrosion or pitting; replace if necessary.

Use ISO VG 32 or the manufacturer's recommended lubricant to lubricate.

D. Testing and Reassembly

Reassemble components by adhering to the reverse disassembly process.

Conduct an air leak test by applying air pressure and inspecting for any breaches.

Ensure seamless movement by conducting a cycle test on the actuator.

3. Tips for Preventive Maintenance

✔ Conducting monthly inspections:

Perform an inspection of the air filters, regulators, and lubricators (FRL units).

Use soapy water to inspect for leakage; bubbles are indicative of leaks.

✔ Quarterly Maintenance:

Use pneumatic tool oil to lubricate the movable components.

Verify the functionality of the solenoid valve.

✔ Annual Maintenance:

Replace all wear-prone components and gaskets.

Clean and relubricate the actuator.

4. Safety Considerations ⚠ Consistently:

Prior to servicing, the system should be depressurized.

To prevent component damage, employ appropriate instruments.

Please adhere to the torque specifications provided by the manufacturer. Never:

Use lubricants that are silicone-based, as they have the potential to damage seals.

Do not overtighten the fittings, as this may result in fractures.