The Benefits of scotch-yoke Type Pneumatic Actuators

Introduction

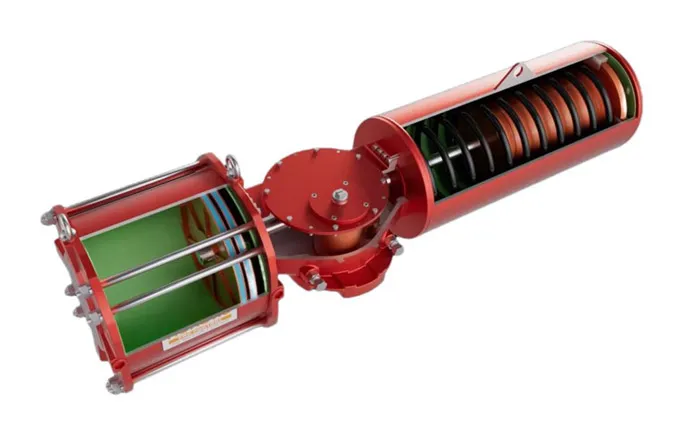

Scotch-yoke Type Pneumatic Actuators are extensively employed in a variety of industrial applications as a result of their high reliability, precise motion control, and robust design. These actuators are indispensable in valve automation, material handling, and assembly lines, as they convert compressed air energy into linear or rotary motion. This article investigates the primary benefits of scotch-yoke Type Pneumatic Actuator in comparison to other actuator types.

1. Stability and High Torque Output

A scissor-like mechanism is employed in the design of scotch-yoke Type Pneumatic Actuator to ensure uniform force distribution, which enables them to produce a high torque output with minimal air consumption. Their rigid construction minimizes backlash, thereby ensuring superior stability and precision in heavy-duty applications.

2. Space-Saving and Compact Design

scotch-yoke Type Pneumatic Actuator are ideal for installations with restricted space due to their compact and symmetrical structure, which distinguishes them from bulkier piston actuators. Their construction is both durable and lightweight, which enables them to be easily integrated into machinery arrangements that are compact.

3. Reliable and Smooth Operation

Smooth motion transmission is guaranteed by the fork mechanism, which minimizes the wear and strain on internal components. In comparison to rack-and-pinion or vane-type actuators, this leads to an extended service life and reduced maintenance requirements

4. High Precision and Repeatability

scotch-yoke Type Pneumatic Actuator are the optimal choice for applications that necessitate precise movement due to their exceptional positional control. Their linear or rotary motion can be precisely calibrated to guarantee consistent performance in automated processes.

5. Resistance to Corrosion and Contamination

Many scotch-yoke Type Pneumatic Actuator are designed to withstand hostile environments, such as chemical plants, marine applications, and food processing industries, due to their use of high-quality materials like stainless steel, aluminum, or corrosion-resistant coatings.

6. Cost-Effectiveness and Energy Efficiency

In general, pneumatic actuators are more energy-efficient than electric actuators, which necessitate continuous power, as they only utilize energy during movement. Operational costs are further reduced by scotch-yoke type designs, which optimize air usage.

7. Applications Versatility

scotch-yoke Type Pneumatic Actuator are compatible with a variety of valve types, including ball, butterfly, and plug, and can be configured to perform a variety of motions (single-acting, double-acting, or spring-return). They are frequently employed in the following applications:

Pipelines for oil and gas

Facilities for the remediation of water

Heating, ventilation, and air

Pharmaceutical manufacture

Automation and robotics

In conclusion,

scotch-yoke Type Pneumatic Actuator are the preferred choice in industrial automation due to their compact design, precision, durability, and high torque. Their adaptability to demanding environments, energy efficiency, and reliability guarantee long-term performance with minimal maintenance. Fork-type pneumatic actuators continue to be a viable option for a diverse array of applications as industries continue to pursue efficient motion control solutions.